ADVANTAGES

Communicate Status

When machines and workstations are equipped with tower lights, andon lights, and/or multicolor strip lights, they can quickly communicate their operating condition to people working nearby, providing at-a-glance knowledge of status and performance, and accelerating the identification of problems so they may be solved quickly.

Andon lights attached to workstations allow operators to press a button that selects a specific light color to notify managers if everything is okay, if they need raw materials, or if they cannot do their job. This keeps workers from spending unnecessary time walking around looking for help and letting help come to them instead.

Andon lights are crucial for maintaining efficient productivity and reducing downtime spent troubleshooting problems.

Tower lights installed on lathes and milling equipment can tell people exactly which step of the process the equipment is in. This enables one person to operate more than one machine as they can see where each one is in the process.

Strip lights connected to analog sensors conveniently display information about fill level, part size, piece positioning, and guidance so operators can quickly identify problems and make adjustments.

Multicolor LED strip lights from Banner Engineering offer high quality lighting and long-lasting low maintenance operation.

Light Guidance

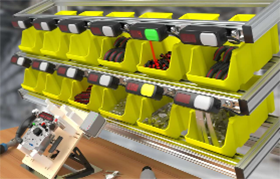

By using pick-to-light buttons, guide spotlights, and verification arrays, workers are easily shown where pallets need to be dropped, parts need to be picked, and boxes need to be placed, helping to reduce cycle times, error-proof processes, and streamline training.

Applying pick-to-light buttons helps error-proof the assembly process by directing workers to specific bins to get parts so that all the correct parts are picked and used in the right order. These lights also help identify when the wrong part was picked, immediately notifying the worker via the light. Additionally, pick-to-light helps reduce training time by guiding people through the process automatically.

Pick-to-light devices and systems help industrial automation manufacturers reduce the risk of error in the assembly process, ensuring product quality and reducing cost.

A similar but larger-scale application for pick-to-light is when high-power guide spotlights are used to illuminate areas where pallets need to be both picked up and placed without obstructing the work area.

Tower light and strip light segments can be activated based on process step completion or time elapsed during an assembly step. This shows workers where they are in the process and provides task time guidance to keep the line running smoothly.

Bright, High Quality Strip Light for Advanced Illumination Indication and Information

Work Area and Task Illumination

Providing adequate light for people in work areas or supplemental light for performing specific tasks helps boost worker productivity and improve product quality. Additionally, energy-efficient lights help reduce energy costs.

Inspection lights help provide workbenches, assembly stations, and visual inspection stations and tunnels with bright, even light, increasing worker productivity, ergonomics, and providing illumination exactly where it is needed, allowing operators to monitor processes effectively while completing automated and manual tasks.

At 15 mm, the WLS15 can fit in tight spaces that other lights cannot. Installs in minutes without impacting existing application framework. Globally certified and supported by Banner.

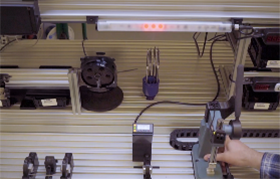

Strip lights installed in control panels give maintenance technicians better visibility compared to typical alternatives such as handheld lights. Better control panel lighting helps technicians when installing or replacing components, troubleshooting wiring errors, and reprogramming PLCs.

Incorporating colored LEDs into standard illumination products gives a 2-for-1 combination of illumination and status indication, allowing operators and supervisors to focus on the work area but still get status change updates.

Enhance your Visual Management Efforts with Banner’s Lighting and Indicators

- Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

- RFID

- Snap Signal

- Sustainability

- TAS – IIoT Service Platform

- The Visual Factory